By: B. Denise Hawkins

New Facility and Equipment Place Morgan at the High-Tech Vanguard

On a recent spring day inside the bright, modern and expansive fifth-floor learning labs, the whir of Juki industrial sewing machines and the buzz and churn of large pattern plotter printers fill the air, as students stitch, pin and hover with care over garments in the making.

Moving from a roomy cutting table to an ironing board, Alexander Edgecomb, a Morgan State University junior, spends several minutes pressing, with perfection, each leg of the men’s denim trousers he will assemble and sew.

“Creating clothes and designing are my passions. Being here at Morgan and having this opportunity to learn to create clothes and style others, and surround myself with peers who are doing the same thing, has been a blessing,” says Edgecomb, who is waiting eagerly to learn whether he will land a summer internship at one of the nearly dozen apparel companies he applied to, from the East Coast to the West Coast — including the owners of brands such as Balenciaga, Nike, Steve Madden and Baltimore’s Under Armour.

When he arrived at Morgan from his hometown, Washington, D.C., Edgecomb knew he wanted to “study fashion and learn to design clothes,” but finding the right degree program and opportunity at Morgan, he admits, “wasn’t easy at first. I had to ask around.” Edgecomb’s search led him to the Department of Family and Consumer Sciences (FACS), where he enrolled in the Fashion Merchandising Track. He expects to graduate in 2026.

Fashion Merchandising students earn bachelor’s degrees in FACS and graduate from Morgan prepared to enter careers in retail, wholesale and related fields, including buying, merchandising and marketing, says Jacqueline M. Holland, Ed.D., an associate professor and chair of FACS. Although the department, which has enjoyed a long and rich history at the University, doesn’t yet offer a degree in fashion design, the University has produced fashion designers and entrepreneurs like alumna Ngozi Okaro of the Class of 1990, a Morgan Political Science graduate. Okaro is an economic, environmental and social justice advocate, and founder of Custom Collaborative, an organization to educate and train “no/low-income women who deserve fair compensation, and thoughtful consumers who want quality clothes that fit and affirm their bodies.” Morgan FACS graduate Adebayo (“Peter”) Olayemi, Class of 2019, owns Eastwood Fashion in Baltimore. An exceptional designer of men’s and women’s apparel, he is considered a master in his field because of his ability to design and create garments without using a pattern.

3D BODY SCANNER

BODY SCAN MEASUREMENTS

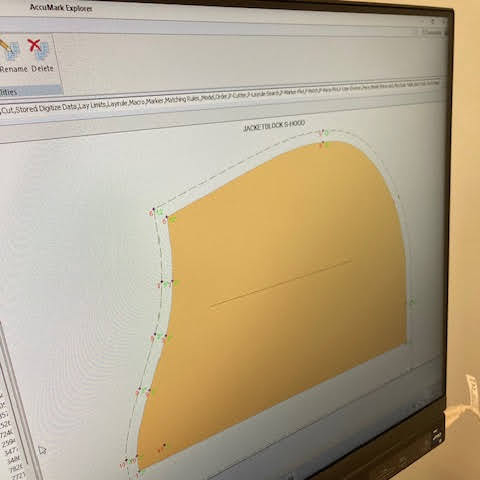

COMPUTER-AIDED DESIGN

What’s in a Name

The Department of Family and Consumer Sciences, formerly the Department of Home Economics, was established at Morgan State College in 1939 and first accredited by the American Association of Family and Consumer Sciences in 2020. The FACS Department enrolls 75 students, with most, 40, in Fashion Merchandising, adds Dr. Holland. The other 35 are in its General Family and Consumer Sciences Track.

Gone, says Holland, is “the little dark room” that for decades was the hub of Fashion Merchandising in the original Martin D. Jenkins Building, on Morgan’s Academic Quad. The space was dotted with basic sewing machines “that needed to be tucked inside their cabinets at the end of the day, some mannequins, and a three-way mirror.”

Today, FACS has a stunning, new academic home on campus, inside the shared, six-story, 208,000-square-foot Health and Human Services Center. The building, which still smells new in some places, opened in October 2024 on the bustling northeast corner of Argonne Drive and Hillen Road.

Cassandra Dickerson, Ph.D., a Fashion Merchandising lecturer at Morgan, hopes the new facility will serve as a calling card for students who want to pursue the fashion side of FACS while learning and creating with the fashion industry’s state-of-the-art design equipment and software.

Whether in the General or Fashion Merchandising Track, FACS students take courses that prepare them for careers in the human sciences, focusing on the needs of individuals, families and communities where they serve. Often, graduates become FACS teachers in public schools across Maryland and the nation. But with a FACS degree, “Our graduates are well-rounded and able to do so many things in the world,” says Dickerson, who came to the department’s faculty in 2012 bearing costume design and wardrobe credits in the Spike Lee movies “Malcolm X” and “Get on the Bus.” She says it was Hampton University graduate Ruth E. Carter, the now lauded costume designer and the only Black woman to win an Academy Award for Best Costume Design, who mentored her on the “Malcolm X” movie set.

Kennedy Davis is a junior studying Fashion Merchandising. She first learned about FACS when she stumbled upon an old YouTube video posted by one of its 2014 graduates. At the time, Davis was a sophomore Business Administration major at Morgan. But after watching the video and exploring the FACS curriculum, she decided to pivot. Getting her mother’s buy-in on changing her major, Davis recalls, meant first explaining the department’s unfamiliar name: Family and Consumer Sciences.

“When I told (my mother) FACS used to be called Home Economics, she said, ‘Oh, OK,’” Davis says. The name Home Economics resonated.

Miya Graham, a junior from Prince George’s County, Maryland, sounds seasoned and is certain about what inspires the fashion-forward look she wants to create one day as a designer. Graham, a FACS student ambassador and president of Phi Upsilon Omicron, the family and consumer sciences honor society, draws on the genius of “Black creatives in fashion” — and on the past. “I take inspiration from 1930s Chanel and Dior and the 1990s when Karl Lagerfeld was really doing his thing with Chanel,” says Graham. “Each era is recycled and evolves.”

Graham remembers making frequent wardrobe changes in her childhoods, as a budding fashionista — at least five a day — until her mother put an end to it when the laundry pile got to be too much. And thanks to her grandmother, who was “more homemaker than seamstress,” Graham also learned early how to sew. Now, in the classroom, she sits down to a Juki brand sewing machine, used by many in the apparel industry.

“It’s so important that Morgan is giving us access to these kinds of machines and other technology used in the fashion industry,” adds Graham, who is also excited to add to her resume the experience she is gaining with this and other tools. “At Morgan, we’re getting a head start on our careers.”

In Morgan’s Fashion Merchandising Track, what’s learned in the classroom is only part of the picture. There are internships, industry collaborations and travel, among other forms of learning. “A promising partner,” says Dickerson, has been Baltimore’s Under Armour.

“It’s been a pleasure to work with Dr. Holland, Dr. Dickerson and their students in the Department of Family and Consumer Sciences,” says Adam Bayer, Under Armour’s senior director of Product Solutions & Athlete Intelligence.

“Our relationship with and support of Morgan State University goes beyond athletics,” Bayer adds. “We have proudly supported the program with career shadowing opportunities, equipment gifts, maintenance assistance, training in the sewing lab and by providing materials for design students to use in their projects. We look forward to continuing this partnership and exploring new ways to connect and collaborate.”

Fashion Meets Technology

As the afternoon sun beams through wide windows along the fifth- and sixth-floor corridors, Holland is proud and beams, too. “We have the best site view from here,” she says, as she points south. In the distance, Baltimore’s downtown and skyline are in view.

And what she sees inside is “10 times the space that we had before,” says Holland of the sleek, airy FACS classrooms, offices, labs and other creative spaces. As her Fashion Merchandising students learn about things like millinery, apparel design, footwear, printing, textiles, manufacturing and the science of it all, fashion intersects with technology. As in industry, technology and state-of-the-art equipment are what Morgan students are using to ensure an apparel product’s best fit, quality, use, strength and feel — not just its good appearance.

Since the COVID-19 pandemic, say industry leaders, there has been a significant increase in the use of technology among designers and merchandisers in the fashion world. And at Morgan, the Fashion Merchandising Track is keeping pace, says Dickerson, an expert in textile technology management. When FACS was preparing to move from the Historic Jenkins Building, Dickerson wanted to ensure that students had access to the latest and most efficient industrial fashion technology and software needed to make them competitive, knowledgeable and career ready.

Dickerson shows off an electronic yarn scanner, which is playing an increasingly important role in the fashion industry by improving quality control and streamlining production. Practically speaking, one way a designer can use the scanner is to make informed decisions about the strength, density and suitability of fabric and yarn to construct a garment worn by someone who may need the ease of accessible clothing, for example, or garments that are breathable and warm. In another lab, two long and large pattern plotter printers flank a wall. In the fashion industry, plotters are used to create designs, patterns and templates for clothing production. The Fashion Merchandising students are gaining experience using pattern plotters in Dickerson’s Flat Pattern class and for creating fashions for the upcoming Department fashion show.

But the quiet showstopper and centerpiece of the new fashion equipment in the department, a German-made, 3D body scanner, stands more than 7 feet tall in a clinical-looking room that adjoins one of the labs.

On this day, Dickerson programs the scanner from a desktop computer in the room. Davis, her student-model, is dressed in black footless leggings and a matching T-shirt and has her hair pulled up. Minutes after Davis steps inside and closes the scanner’s doors, Dickerson’s computer screen shows an exact three-dimensional avatar of the student, created using a combination of cameras positioned around Davis’ body.

High-tech body scanners like the one at Morgan hold the key to creating — and selling — bespoke apparel. This technology captures a person’s body type and more than two dozen measurements, which can be converted into a digital pattern that serves as a blueprint for a garment that will fit Davis perfectly, says Dickerson. Having equipment like this has made Morgan’s FACS Department one of the most advanced fashion design labs in the region.

The opportunity the body scanner provides to collaborate with engineering, architecture, nursing and other departments is one of the reasons Holland is so excited about the future of FACS at Morgan.

“It’s about how we use our research in supporting individuals and families to successfully navigate life,” says Holland. “This is what propels our work in FACS.”